Structural Integrity Starts with Design, Not Just Material

While material quality is critical, roll cage performance depends on more than just the tube. It’s worth briefly noting that industry experience consistently shows failures often stem from factors beyond the material itself, including:

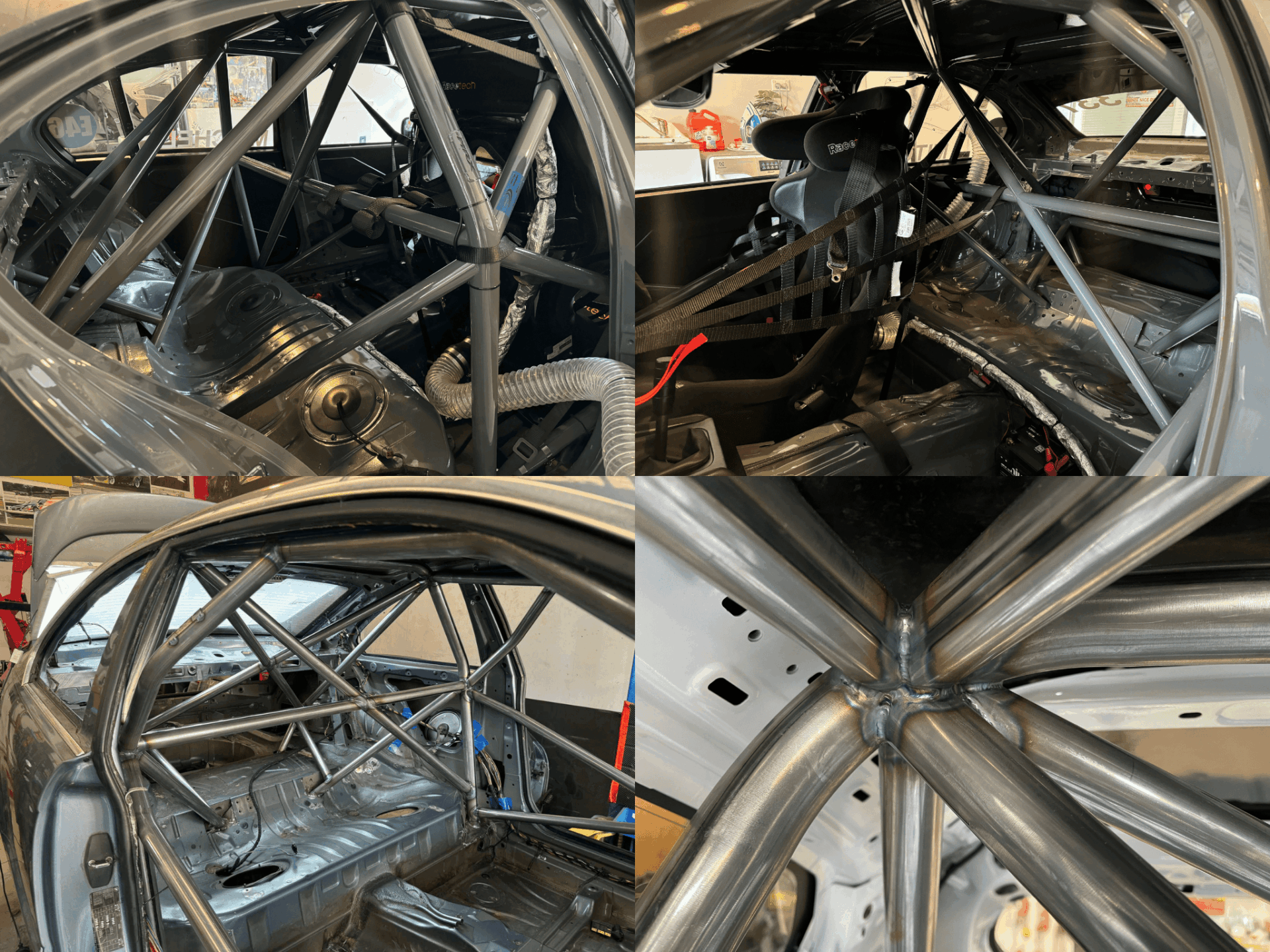

- Weld Imperfections: Poorly executed welds at joints or base plates can create stress concentrations and become failure points under load. Issues like lack of fusion, undercutting, or porosity can compromise the structure regardless of tube quality. Welds should be consistent, full-penetration where required, and ideally inspected – especially in critical areas.

- Design Flaws: Poor triangulation or inadequate bracing can limit the cage’s ability to distribute forces effectively. Without proper geometry, tubes may buckle or deflect during impact. Strategic placement of diagonals and load paths is essential for strength in all directions.

- Mounting Issues: Attaching cage tubes directly to thin sheet metal, without reinforcing underlying structures like chassis rails, can lead to serious failures in a crash. A strong cage starts with high-quality tube, but it must be paired with competent fabrication and proper load path integration to perform as intended under impact.

Supporting Consistency and Clarity in Safety Standards

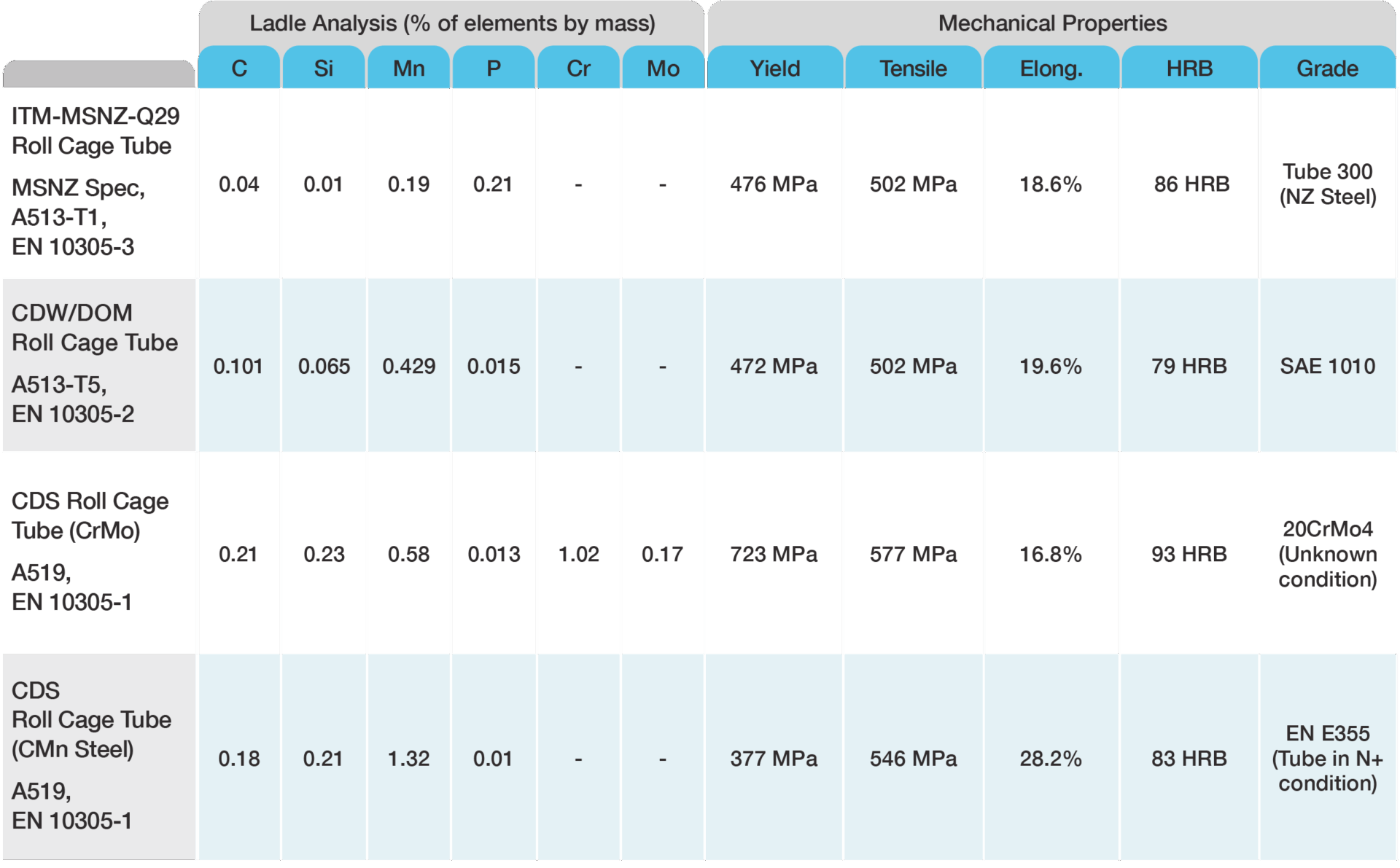

Established frameworks like FIA Appendix J, Motorsport Australia’s Schedule J and Motorsport New Zealand’s Appendix Two, Schedule A provide critical safety benchmarks by specifying minimum materials and mechanical properties. From our experience working with fabricators and engineers, especially at the grassroots level, we’ve observed some areas where greater clarity could support both compliance and safety outcomes.

To that end, we believe the following ideas – developed through practical experience – could benefit the broader community:

- Standardised reporting formats for mechanical and chemical properties, making documentation clearer and easier to assess. This shows manufacturer commitment to the industry and illustrates fit-for-purpose products.

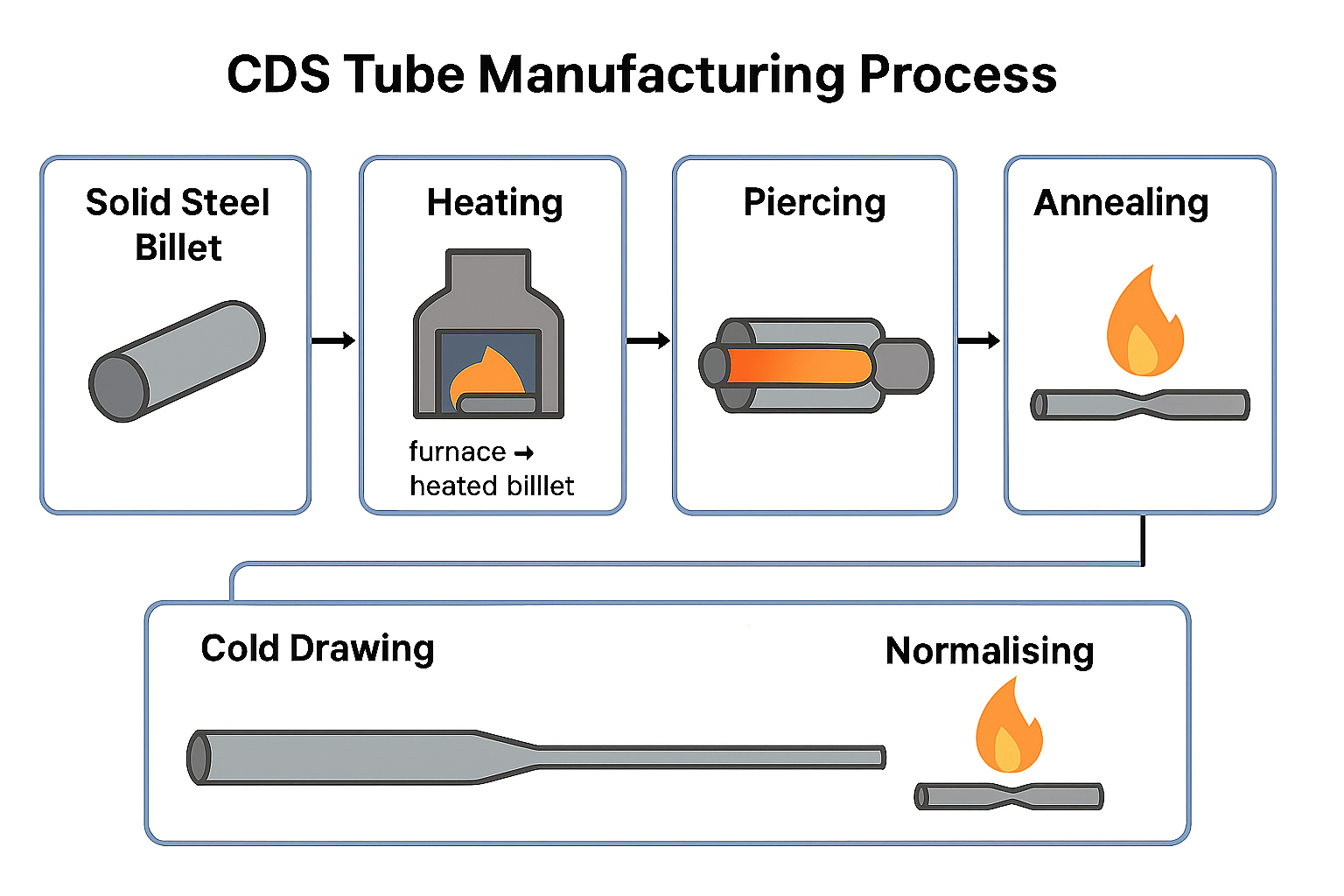

- Greater transparency around manufacturing processes such as normalising, cold working, and seam welding, which have a direct impact on real-world tube performance.

- Recognition of modern, certified HFIW tubing, which in many cases meets or exceeds CDS and DOM in terms of strength, ductility, dimensional control, and material consistency.

- Updated Yield Strength Criteria for Select Applications: Enabling the use of certified high-strength tubing with slightly thinner walls (e.g. 2.6 mm vs 3.0 mm) in Drag and Speedway categories could address the limited availability of >350 MPa yield mild steel material – while maintaining or improving safety margins.

We offer these suggestions not as criticisms, but as a contribution to ongoing conversations around safety, fabrication, and performance in motorsport.

Proven Performance in Practice

All the products we’ve tested in this case are broadly fit for purpose and performed well under destructive testing, with acceptable roundness and concentricity. But not all tubing is created equal – differences in steel grade, process control, and traceability can have a significant impact on weldability, consistency, and structural performance under load. In some instances, we found that tubes marketed under common designations varied significantly in their actual composition, highlighting the importance of verifying material properties rather than relying solely on nominal specifications.

Importantly, our testing confirmed what we’ve seen in practice for over a decade: properly manufactured HFIW tube not only holds up – it performs. With good ductility, high weld zone integrity, and consistent mechanical properties, it stands as a reliable alternative to CDS and DOM for safety-critical applications. At Industrial Tube Manufacturing, we believe safety starts with quality – not just in the tube, but in the standards, transparency, and traceability behind it. Our commitment to locally made, certified steel, precision manufacturing, and proven testing methods has earned the trust of fabricators and scrutineers.

For fabricators, engineers, and competitors alike, asking the right questions matters:

- Where was the tube made?

- Is it certified and traceable?

- Are the mechanical properties independently verified?

These questions aren’t just box-ticking – they’re the foundation of safer, stronger structures that hold up under pressure. When the right material is selected, and its specification is backed by verified properties, controlled processing, and full traceability, real-world performance isn’t just expected – it’s engineered.

For more information or to discuss your requirements, contact us today.