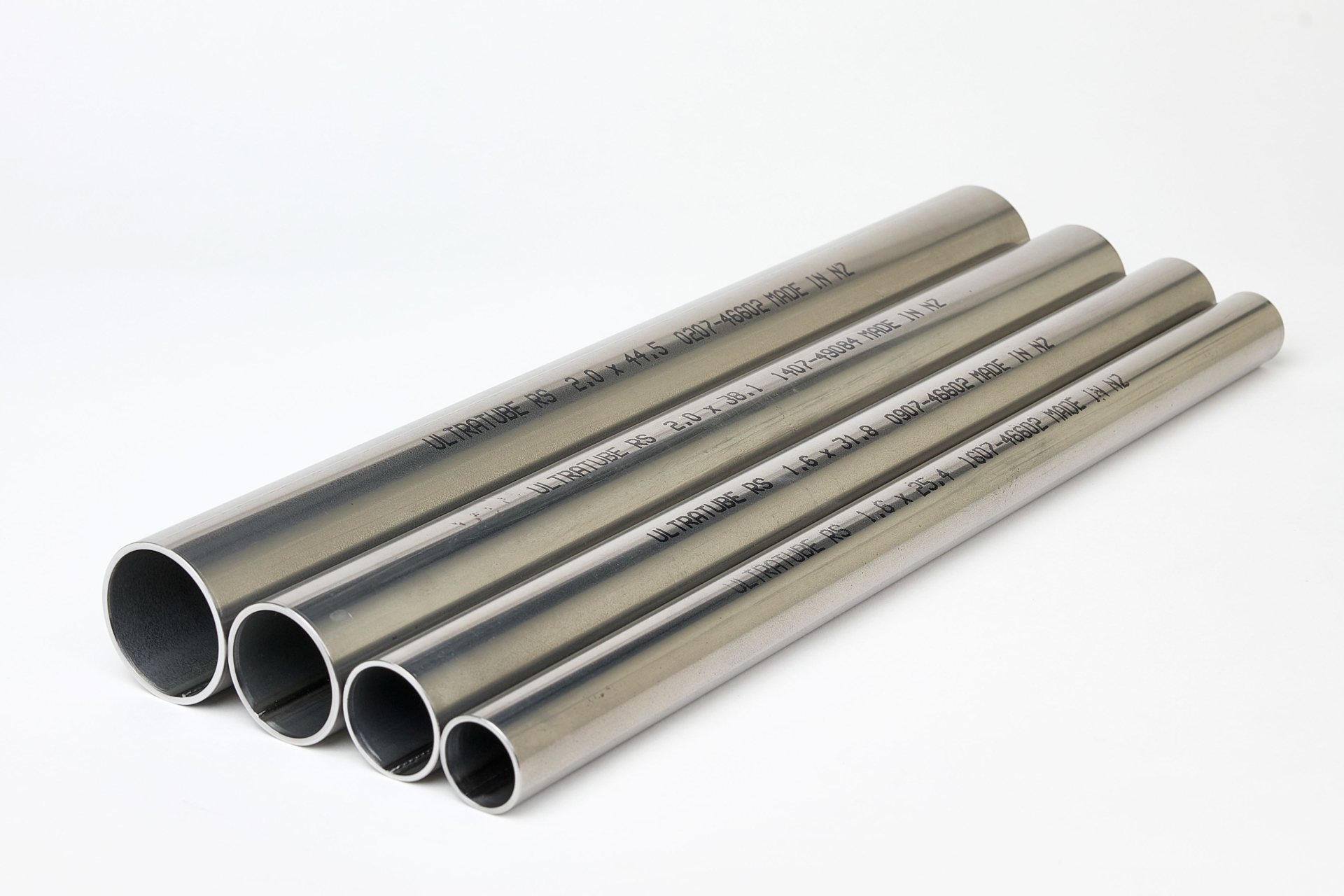

UltraTube™ Specifications

UltraTube™ is a high-performance steel tube made from advanced dual-phase (DP) steel. Its ferrite–martensite microstructure offers a unique combination of high strength, good ductility, and excellent weldability.

Base Material

Made from EU-sourced cold-rolled dual-phase steel, UltraTube™ offers significantly greater yield strength than conventional mild steel grades.

Key Benefits

- Engineered for strength

- Trusted for safety

- Optimised for efficient fabrication

UltraTube™ maintains a good level of formability, excellent weldability, a smooth surface finish, and highly consistent mechanical properties. Enables thinner-wall designs in frames, components, and load-bearing structures where strength and durability are critical.

Certified, Traceable, and Made Locally

Manufactured in New Zealand to AS/EN standards with full mill certification and traceability. Backed by local technical support, an extensive distributor network and fast delivery across Australasia.