Mechanical Testing

During the manufacturing process, our tube undergoes a series of in-house mechanical tests, measurements and inspections to ensure it consistently meets the desired specifications and standards.

- Flare test: Outside diameter increased by up to 25%, dependent on profile or material type, without failure to either the base material or the weld zone.

- Flattening test: Capable of being flattened without cracking between two parallel planes with the weld zone located at both 90 and 0 degrees.

- Surface examination: Visual inspection for external surface damage. Straightness, twist, weld position and weld bead height are tested to meet internal and external standards and/or customer specifications.

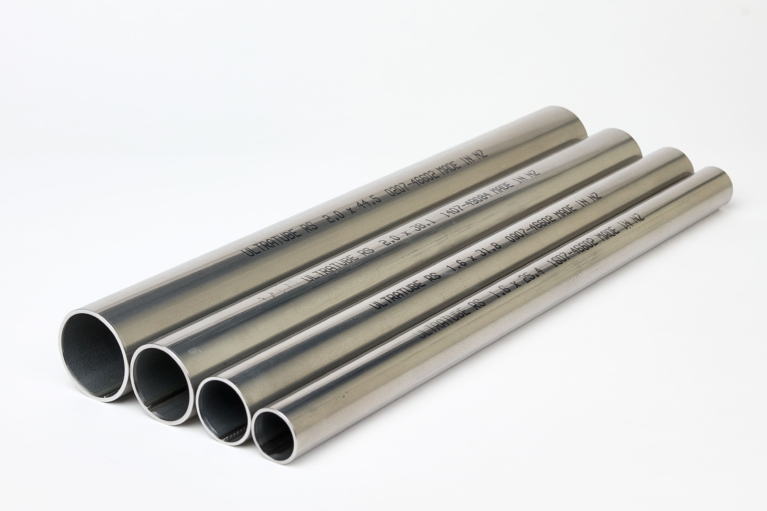

- UltraTube is subject to a distinct mechanical testing methodology. Some of the above details may not be directly applicable. Specifications are available on request.

Mechanical Properties

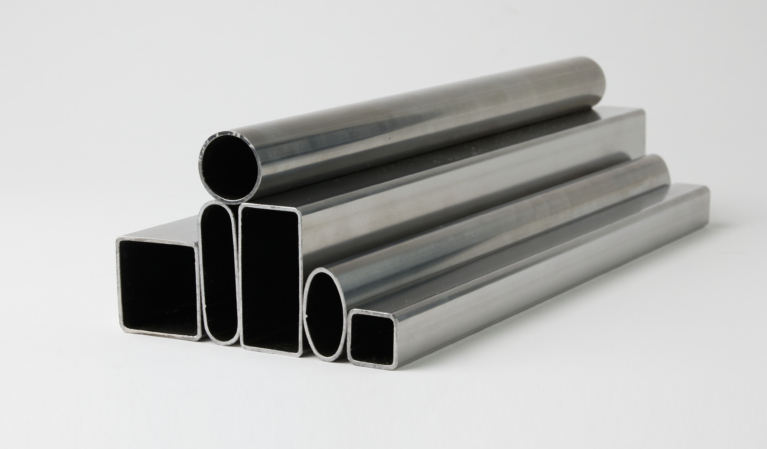

During the tube-forming process, when the steel strip is shaped into tubular profiles, the mechanical properties change.

The degree of this change is influenced by the specific dimensions of the tube being manufactured, especially the diameter to thickness ratio (D/T). Typically, during the tube-forming process, the yield strength experiences a significant increase, the tensile strength sees a slight increase, and elongation is reduced.

The thickness of a material does not directly influence its yield strength. However, thicker materials can endure higher stresses before deforming, which indirectly impacts the yield strength. As an example to illustrate how tube forming effects the mechanical properties of the base material, test data of formed profiles from the same slit width are below.

Note: Tested to AS 1391. Rectangle test sample taken from the 50.8 side. The above mechanical properties are from a specific coil batch and mill run/s and are to be treated as such. When full test certificates are required for a specific product, this must be requested at time of order and an additional charge applies.