Mechanical Charateristics

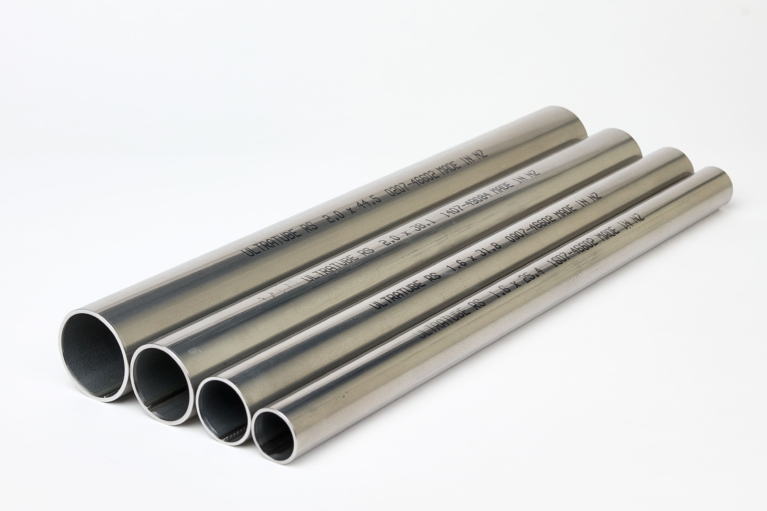

The mechanical characteristics of UltraTube RS™ – high energy absorption, excellent fatigue resistance, and consistent performance – make it well-suited for safety cages, space frames, commercial vehicle fit-outs and heavy-duty off-road accessories. Its ability to deform in a stable, controlled manner helps maintain a low deceleration pulse during impact, improving crash performance and occupant protection.

Dual-phase steels exhibit continuous yielding, transitioning gradually from elastic to plastic deformation rather than showing a distinct yield point. This results in more predictable behaviour during both forming and impact scenarios.

The cold-rolled coil used to manufacture UltraTube RS™ is produced through intercritical annealing on a continuous annealing line (CAL). This process precisely controls phase transformations to achieve the dual-phase structure, ensuring uniform thickness and consistent mechanical properties throughout the coil and into the final tube.

Note on Mechanical Properties:

The ITM-MSNZ-Q29 standard requires a minimum base material (strip) yield strength of 250 MPa and does not mandate batch specific tensile testing on the finished tube. While Industrial Tube periodically undertakes tensile testing to AS 1391 where required, and results consistently show yield strength well above 350 MPa, a yield strength is not guaranteed for every batch unless tensile test data is specifically ordered by the customer.

UltraTube RS™, is subject to a more defined test regime. Multiple tube profiles are tensile tested to AS 1391 from each coil batch, verifying a minimum 650 MPa yield strength across the UltraTube RS™ size range. Testing is repeated with each new coil batch, and full certification is supplied with every order. Batch and coil numbers are printed directly on each tube length at regular intervals, providing full traceability.

Note on sizing (imperial equivalence):

Typical imperial mechanical-tubing standards—ASTM A513, ASTM A519, and AMS-T-6736—specify wall thickness tolerances of approximately ± 10 %. UltraTube™ 1.6 mm and 2.0 mm nominal walls are targeted at 1.65 mm and 2.02 mm actual to align within the 0.065 in (1.65 mm) and 0.083 in (2.11 mm) imperial ranges. This ensures compatibility with imperial tooling and fit-ups while remaining compliant with EN 10131. Minor variation may occur between coil batches within the same tolerance band.