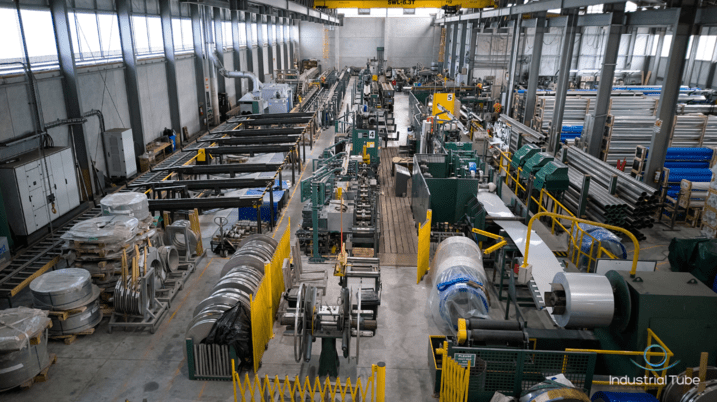

NON-DESTRUCTIVE & VISUAL TESTING

Eddy-current testing

Continuous weld testing is done in-line using MAC’s® ECT units with sector (where appropriate, encircling) coils. This allows us to measure any anomalies in the weld area and exception notification is through an external horn and dedicated displays. Calibration is tested for every run and professionally calibrated annually.

Surface & Straightness (Visual)

External and internal surface is visually inspected for dents, pickup, and scratches. Any internal markings are checked using the visual inspection scope. Straightness is tested against a benchmark by being rolled and turned. Any tube not passing the straightness test is mechanically straightened off-line.

Weld

Internal surface weld heat-tint. We aim for 1-2 on the straw chart and fit well within the “pale straw” level 3 as per AWS D18.1M.

Wall thickness

Every coil strip is tested for thickness at the start and finish of the coil, and every 1-2 hours while the mills are in operation.

Ovality

This is measured and adjusted in-line, with measurements taken on 4 axes to achieve an average. Additional adjustment is built into the mill to consistently achieve narrower tolerances than the AS 1528.1 standard. This varies from a 30% tighter tolerance <31.8mm to 80-90% tighter tolerances at 203.2mm and improves fit up for the fabricator when purge welding fittings to the tube.

DESTRUCTIVE TESTING

Ra & Rt Test

We use a diamond tipped Ra Meter, which can perform Ra and Rt tests simultaneously. Testing equipment is located close to the mill, allowing for prompt action on results when necessary. Roughness testing is conducted to ISO 4288 on all tube sizes larger than 31.8mm. We take a minimum of three samples across the weld zone and three across the cold working zone. Typically, we achieve in the range of 0.2-0.6μm Ra and 2.0-6.5μm Rt on the weld zone.

Flange Test

This is designed to exceed the standard requirement for finished angle and percentage of material flanged. We conduct this test with the piece we flare, flanging and then crushing the tube, ensuring the tube does not fail.

Flare Test (not required by AS 1528.1)

Flared using a 60° cone and expanded to the minimum required, then expanded further to ensure a safety in the testing.

Reverse Flattening Test

Tube is split longitudinally then flattened with a 60t press brake, with the weld positioned in the centre of the sample.

Reverse Bend Test (not required by AS 1528.1)

Reverse flattened samples are folded back on themselves and compressed until both sections of the sample either side of the weld are touching. Our reverse bend is done at 2–2.5x the wall thickness (almost flat), while the standard allows for the fold to be 4 times the wall thickness.

To summarise, we undertake a series of tests as per AS 1528.1 and our internal standards. These are designed to eliminate any areas that may affect product performance; both from the manufacturing process and the input material. Hygienic-Tube™ is line marked with our identification – ITMNZ HYGIENIC–TUBE – and the information required by the standard to ensure full batch traceability. Test certificates are provided as per EN 10204 Type 3.1. We manufacture from 6.35-203.2mm (1/4” – 8”).

Industrial Tube Manufacturing’s Hygienic-Tube™ can be specified when ordering from your local steel distributor.