How Cold Forming Alters Steel Tube Strength and Ductility

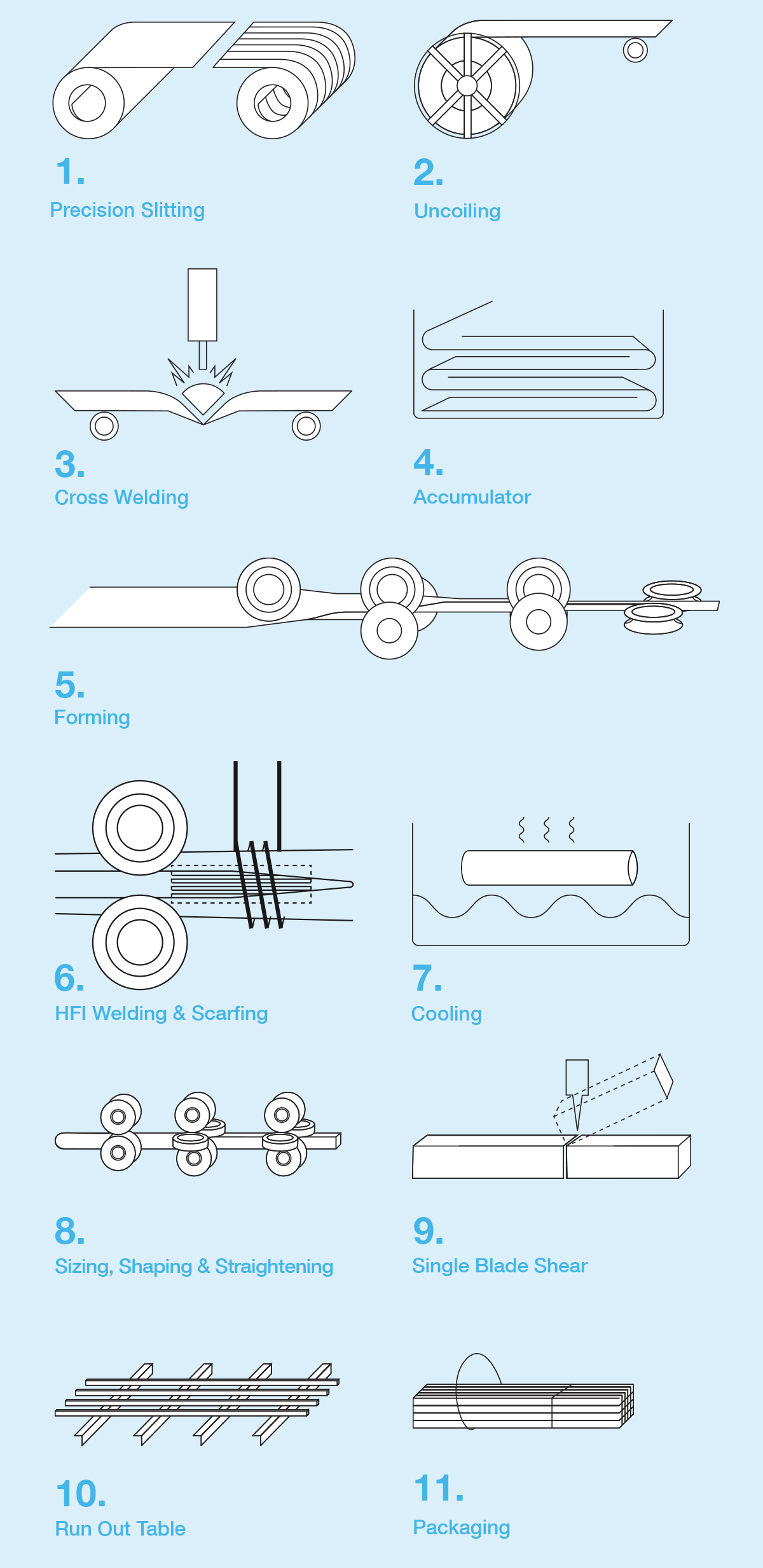

During tube manufacture, steel strip is passed through a series of rollers in a process called cold forming. The rollers gradually shape the strip into a tube. This process includes several stages of forming and sizing, depending on the final tube dimensions. As the tube is formed, the mechanical properties of the steel strip undergo significant changes. Understanding these changes is essential for ensuring the tube meets the required strength, durability, and performance standards across various applications.

As the strip is progressively shaped into a tube, it experiences plastic deformation, leading to work hardening. This process alters key mechanical properties, including strength, hardness, and ductility, ultimately affecting the tube’s performance and characteristics.

Several other factors influence these property changes, including the input material (strip) composition, the number of forming and sizing stands, and the final tube profile.