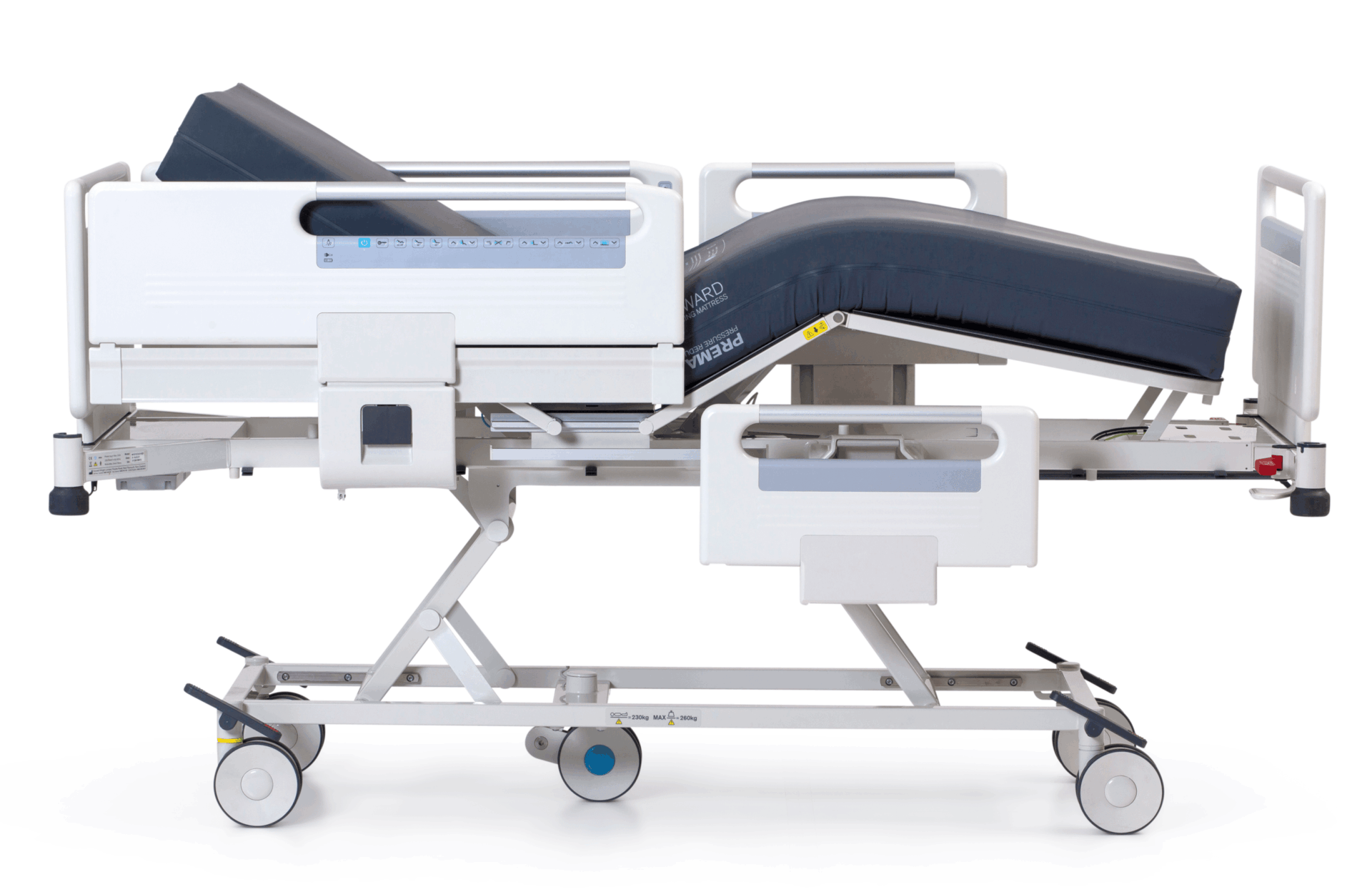

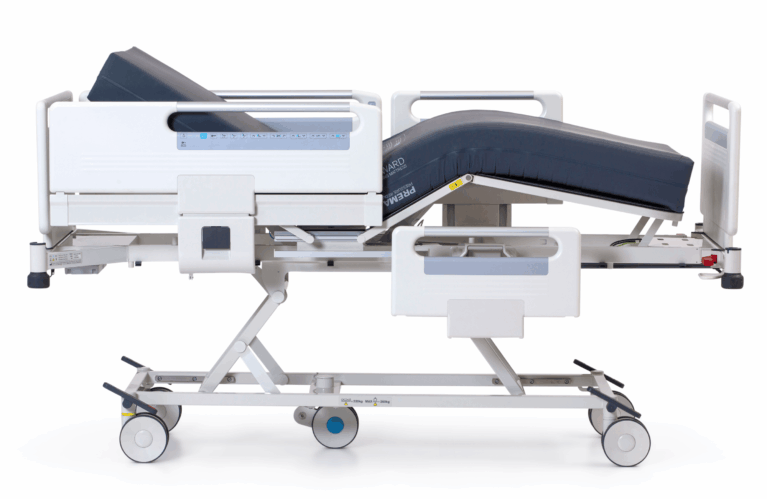

The Customised Solution

Industrial Tube Manufacturing worked closely with Howard Wright to develop a custom tubing solution that balanced strength, stability, and manufacturability.

After trials and tensile testing, the team selected NZCC-1P, a single-pass cold-rolled steel produced by New Zealand Steel at Glenbrook. This locally manufactured material not only met the technical targets for strength and dimensional stability but also supported our joint drive for as sustainable as possible, locally sourced steel made locally in New Zealand.

NZCC-1P provided:

- Higher yield strength compared with annealed strip.

- More stable dimensions compared with full-hard material.

- Excellent roll-forming behaviour for rectangular profiles.

To accommodate the higher-strength steel strip, Industrial Tube implemented proprietary adjustments to the tube-mill setup—refining roll pressures, forming-stand alignment, and scarfing control—to ensure consistent forming without compromising weld quality. Internal weld beads were controlled using in-process ID plugs, maintaining tight internal clearances.

The resulting 1.6 × 50.8 × 25.4 mm tube achieved ± 0.13 mm OD tolerance and < 4 % wall-thickness variation, exceeding the precision required for telescoping assemblies.

Testing and Validation

Tensile tests conducted to AS 1391 (2020) confirmed that the 1P tube met and exceeded specification: