40 years of manufacturing with purpose:

Industrial Tube positions for the next wave of growth

As offshore competition continues to put pressure on New Zealand manufacturers, one Waikato business is marking 40 years of local production with the same founding philosophy it started with: build capability at home, invest in people, and give more to the region than you take.

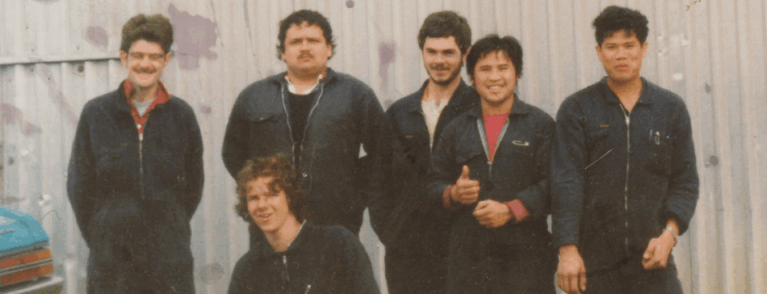

Industrial Tube was founded in Hamilton in 1985 by Peter and Margaret Green, who believed New Zealand could and should manufacture more of its own high-quality products. What began as a small tube mill has grown into one of the country’s only precision steel tube manufacturers. The company has become a long-term manufacturing partner to many of New Zealand’s most trusted brands in food, horticulture, transport, infrastructure and engineered products.

Today the company employs around 55 people at its Hamilton base, with a further five nationally. And while its scale has grown, the ethos remains the same: local jobs, local skill, local supply, and long-term commitment to New Zealand industry.

When Industrial Tube opened, it manufactured a single product: cold-rolled mild steel tube. As customer needs evolved, so did the company’s capability. It now manufactures tube in eight different steel types; each tailored to performance in specific environments.

Close-annealed tube is used in furniture, shelving and automotive interiors. Hot-rolled pickled and oiled steel suits racking, cargo barriers and seat frames. Pre-galvanised tube supports outdoor structures, fencing and orchard systems, while specialist automotive tube is used in roll cages and exhausts. Stainless steel serves the food, beverage and dairy sectors – from processing lines to milking systems – while architectural stainless appears in handrails and high-spec finishing features.

This specialised range has helped customers reduce offshore dependence and improve product reliability, while giving Industrial Tube a front-row role in helping New Zealand manufacturers innovate.

Where possible, Industrial Tube sources its steel coils from BlueScope New Zealand, meaning many of its products are 100% New Zealand made – from West Coast iron sand through to finished tube. Steel is also a highly recyclable material, and in 2022 Industrial Tube achieved Gold Certification from the New Zealand Sustainable Steel Council, recognising its commitment to responsible and sustainable manufacturing.

Tube manufactured at Industrial Tube is now used everywhere from food and beverage processing facilities and commercial furniture to agricultural infrastructure and outdoor shade solutions.

Where possible, Industrial Tube sources its steel coils from BlueScope New Zealand, meaning many of its products are 100% New Zealand made – from West Coast iron sand through to finished tube. Steel is also a highly recyclable material, and in 2022 Industrial Tube achieved Gold Certification from the New Zealand Sustainable Steel Council, recognising its commitment to responsible and sustainable manufacturing.

Tube manufactured at Industrial Tube is now used everywhere from food and beverage processing facilities and commercial furniture to agricultural infrastructure and outdoor shade solutions.

The past five years have tested every part of the manufacturing supply chain, but Industrial Tube credits its resilience to a disciplined approach.

“We can’t control economic conditions, but we can control how we operate,” says Chief Executive Grant Waring. “We buy well, manage costs, look after our people and stay close to our customers. That’s what got us through.”

General Manager Werner Petrick says diversification of both product and service has also been pivotal.

“Imports are a reality of global supply, so our role is to provide something better – flexibility, precision and customisation,” he says. “One recent customer, for example, was facing huge minimum orders from their offshore supplier. By moving to Industrial Tube, they could scale production to match sales and adapt design much faster.”

Investment in advanced laser, cutting and finishing technology means Industrial Tube can now supply fully engineered components – not just raw tube – allowing customers to move faster and carry less supply risk.

That same philosophy extends beyond manufacturing. Industrial Tube’s founding commitment to giving back remains active today through the Green Charitable Trust, which continues to support community projects throughout the Waikato – a reflection of the company’s belief that long-term local manufacturing should also deliver long-term local benefit.

As demand grows in the food and horticulture sectors, Industrial Tube sees increasing opportunity to support the systems that underpin New Zealand’s export economy.

“There will be significant opportunities in the horticulture and agriculture space driven by new growing and farming methods – enhancing efficiencies, serving increased global demand, and mitigating climate impacts,” Werner says.

That shift is already visible, with growers moving toward permanent steel structures for canopies and trellising due to weather resilience, hygiene performance and product longevity.

Infrastructure is the next big wave. New Zealand has a major infrastructure backlog which will bode well for the industry once a committed pipeline of work is in place.

Werner believes the future will be defined by capability, not volume.

“If New Zealand wants secure supply and world-class food and export systems, it needs local manufacturing. We intend to be at the heart of that.”

For Grant, the next 10 years are about continuing the leadership foundation laid 40 years ago.

“It’s still a family business at its core, and that means thinking generationally. We’re proud to contribute to the Peter Green’s legacy and think he’d be proud that we’ve continued to grow without losing our commitment to people, community, and New Zealand manufacturing.”

Thanking our loyal clients for their support.

End-to-end manufacturing, streamlined. Design, prototyping, and production — all managed in-house for precision and control.